Template just woke up, running smoothly

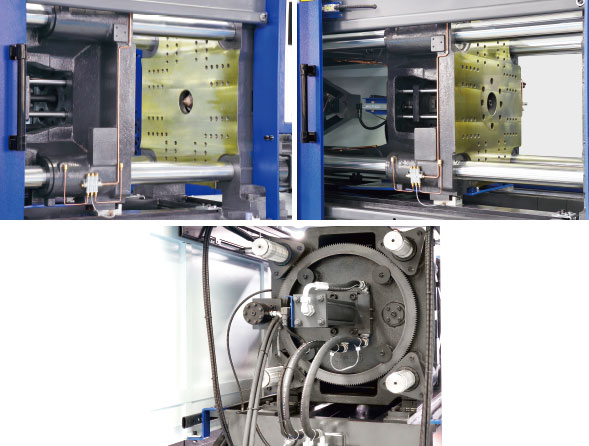

Specifications, increase capacity of mold more widely, strengthen the protection of large, rigid template columns and die, free use of material, environmental protection and clean and smooth appearance, built-in safety bar, free high security adjustment.

Low-pressure mold protection device

Auto mode function

Express clamping function, improve production efficiency

High pressure automatic centralized lubrication system

Enhanced treatment movable platen moves wearable track

Multiple hydraulic ejector mode

Precise injection, stable operation

A short powerful double cylinder injection system and high precision linear guide rail, with low inertia and high response mechanism to ensure smooth injection, injection and template deformation, optimization design of screw assembly, achieve better plasticizing effect. Automatic cleaning bucket, anti salivation, anti cold start delay function, ensure the efficient, convenient and safe.

Holding pressure and back pressure settings

Precise PID temperature control, temperature control accuracy up to ± 0.5 ℃

Non-slip aluminum tread plate

Bijective shift the balance on both sides of the cylinder barrel, make sure the nozzle is not offset, sealing, and not easy to leak glue (3580KN and above)

Electronic foot control injection stroke

Anti salivation function

Automatic function clear material

High-speed motor-driven screw oil pre-plastic device

Screw cold start (prevention) function

Injection shield

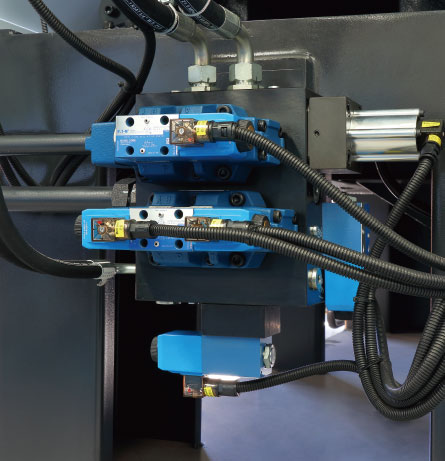

Cylinder automatic heating function

The hydraulic system is advanced by pressure and flow proportional control to achieve fast multi-stage pressure and speed switching, system configuration is reasonable, advanced, stable and reliable operation, the noise is lower than 75dB, in a large machine using two cartridge valve system, improve the system flow and response speed, which makes the best performance.

High precision computer controller combined with high quality, power saving 22%~55%, high economic efficiency. The overall speed of more than 20%, the high efficiency of the machine, so that the formation of multi hole more stable.High precision oil filter full flow filter oil circuit, effectively prevent the pollution and deterioration of hydraulic oil, so that the oil pump, oil valves and other hydraulic components to run more smoothly, hydraulic seals longer life.

Operation excellence performance, user-friendly interface, enhance the sensitivity and stability of the machine, line curve detection function and central connection management, rich SPC quality management interface, is absolutely the best weapon of your profit.

TFT LCD color display, full color, delicate screen

Embedded LINUX system, windows style interface

Real time animation of machine operation

Record of finished product parameters to facilitate inspection of finished products

High precision displacement sensor system, control accuracy of + 0.2mm

The fuzzy control technology is adopted, and the precision of temperature control is 1

Multi input / output port, port function can be configured

With output programmable function

Support USB and network interface (optional)

Parameter data protection lock with power save function

Super capacity data storage

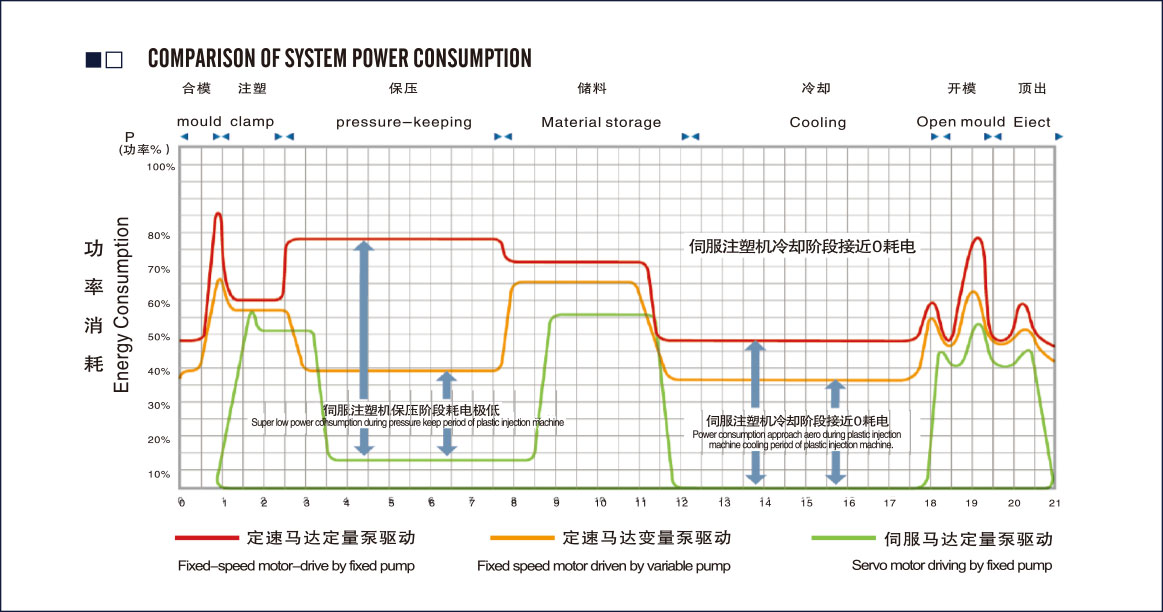

High-end configuration, super power saving effect and superior quality! The servo energy-saving injection molder has its output power changing along with the load change, so there is no waste of excessive energy. The motor at the cooling end doesn’t work with power consumption of 0. The servo energy-saving injection molder can save 20-80% compared with traditional injection molders. So it can bring you true experiences of power saving and great economic benefits.

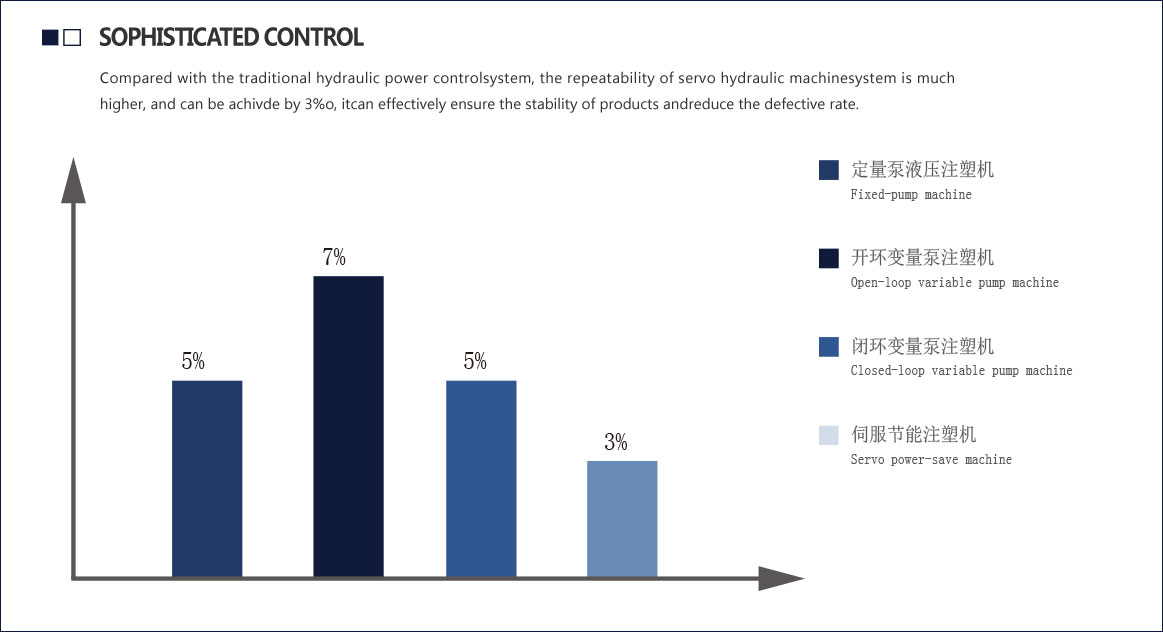

Excellent molding stability

Servo drive system, pressure and flow rate adopt closed-loop control, compared with traditional injection molding machine, molding repeat accuracy is significantly improved

Constant oil temperature

The servo motor outputs hydraulic oil proportionally to avoid excess heat generation. The hydraulic oil does not even need to be cooled to achieve substantial water saving

quick response

The servo drive responds quickly, and the quick start-up time is 50% higher than that of traditional injection

Significant energy saving

Under the same conditions, compared with the traditional quantitative pump injection molding machine, energy saving is 20%-80%

Super performance and environmental protection

The whole machine runs with low noise, and the low-speed operation is more quiet